+86 182 6187 1098

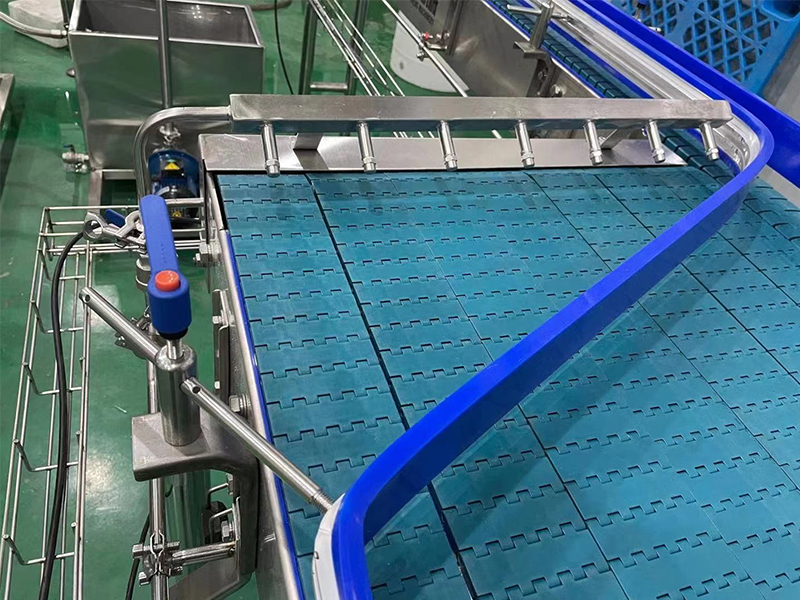

An automatic bottled water filling machine is engineered to streamline the entire bottled water filling line, ensuring maximum hygiene, accuracy, and efficiency. This fully automatic water bottling line integrates advanced technology to minimize manual handling and guarantee consistent output quality.

The complete workflow of a drinking water bottling plant typically includes three main stages:

Bottle Rinsing: Empty PET bottles are first sterilized and washed using high-pressure disinfectant and pure water to remove any impurities, ensuring a clean and hygienic start for the bottling process.

Water Filling: The water filling machine automatically dispenses purified, mineral, or spring water into each bottle with precise volume control, using gravity or pressure filling technology depending on the application.

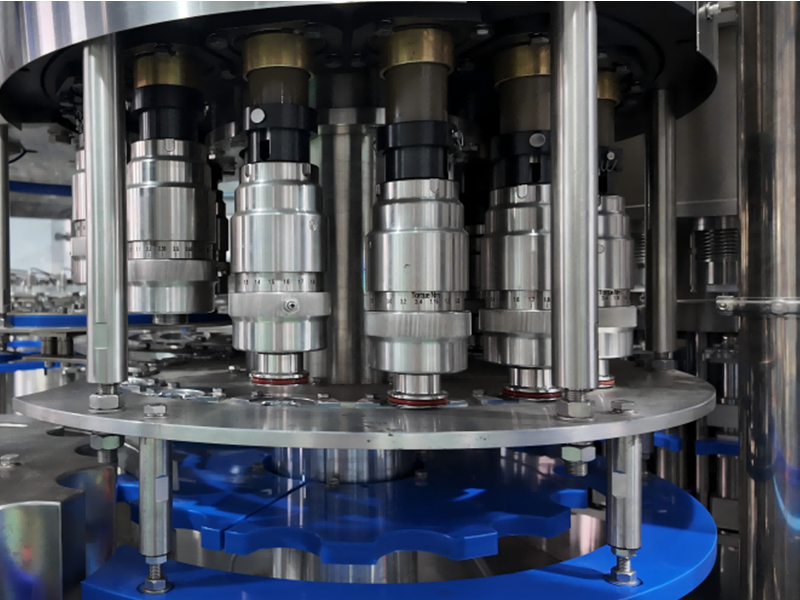

Capping: The automatic capping system securely seals each bottle with screw or press caps, maintaining product freshness and preventing contamination.

| Step 1 |  |

| Step 2 |  |

| Step 3 |  |

| Step 4 |  |

| Step 5 |  |

| Step 6 |  |

| Step 7 |  |

| Step 8 |  |

| Step 9 |  |

| Name | Size | Downloads | Download |

|---|---|---|---|

| Nancheng Product Catalog.pdf | 22.96MB | 75 |

Ready to Build Your Beverage Plant?